Services

CAFM / CMMS

Is a system that enables organizations to track the status of the equipment maintenance tasks, and track the location of inventory, replacement parts, and assemblies, generally located in the warehouse or storeroom of the company.

Evolution of CMMS

Commonly used today by the companies worldwide for documenting, standardizing, and verifying maintenance processes. But, earlier, these tasks were done manually using registers, which was quite a time consuming and cumbersome job. However, CMMS was introduced in 1965 and is still evolving, making it easier for businesses to manage their maintenance tasks with each update. So, let's dive into the important advances of CMMS approximately occurring every 10 years.

At present, the market is much more competitive and relying on spreadsheets, and paper records for maintenance tasks can result in costly repairs, reduce the life of assets, and increase the downtime. With the improvements in support services and software functionality, the companies are embracing CMMS solutions to manage their maintenance activities.

The Future of CMMS is IoT (Internet of Things)

IoT and AI are trending topics in almost every business sector these days. Millions of companies are now looking forward to execute IoT in their CMMS so that the machines can monitor themselves and send real-time data to the managers helping them to avoid sudden failures and accidents in their manufacturing units.

IoT smart devices can monitor usage, helping to plan strategies to save energy costs. Some devices also help the users to turn off HVAC units from their Smartphones. The devices can also put to sleep until any motion activates them.

The IoT enabled sensors can communicate with your CMMS tools to generate work orders automatically notifying that a repair is needed soon. This helps in reducing downtime and increasing efficiency of the technicians.

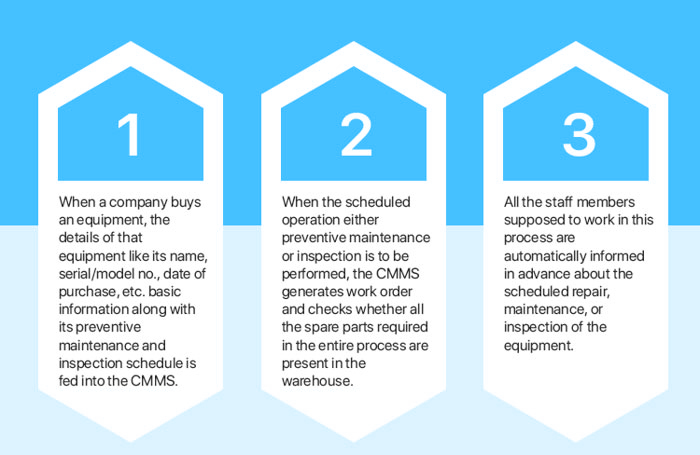

How Does a CMMS Work?

A CMMS is used to streamline three tasks - Inspection, Preventive Maintenance, and Repairs. So, let's have a look at how CMMS can streamline these tasks.

This systematic approach towards preventive maintenance and inspection helps the company in improving productivity and efficiency. At the same time, it also reduces the chances of breakdowns and sudden accidents. The need for equipment repairs also reduces if maintenance and inspection tasks are done in a timely manner.

CMMS can also help you in quickly finding the maintenance team available to perform the tasks relating to inspection, maintenance, and repairs.

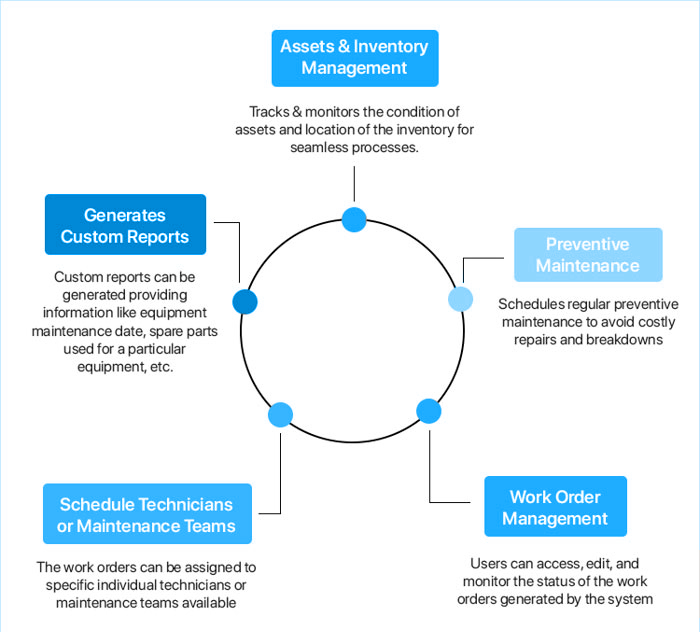

What Does CMMS Do?

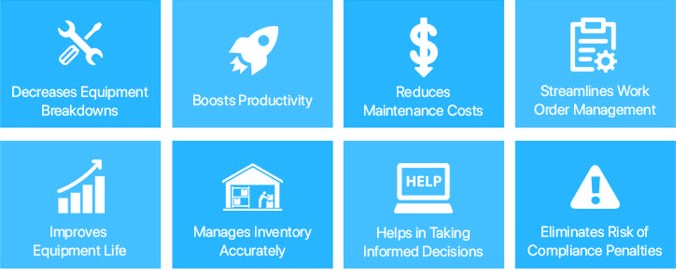

Benefits of Using CMMS

Now when you know how CMMS replaced the manual registers and excel sheets to streamline the entire maintenance process, it also becomes significant to determine the factors to consider while selecting the best CMMS software. So, here is a list of some features:

Work Order Management

The CMMS you select should automatically generate work orders depending on the maintenance schedules and repairs when required. It should facilitate users to assign the work orders to the specific maintenance crew and track it till the job is done.

Purchases

After the need for repairs or maintenance arises, the CMMS system should be able to generate the list of spares required by the technicians and maintenance crew to get that task done successfully.

Predictive and Preventive Maintenance

The CMMS should facilitate you to predict the future maintenance or schedule preventive maintenance based on the age, make & model, usage, etc. Of the equipment. This would help in reducing huge repair costs and improve the efficiency of the equipment.

Asset Management

There are several types of equipment & machineries at different geographical locations, which you need to monitor and keep track of. An efficient CMMS should help you in accessing the information and managing these assets quickly and accurately.

Inventory Control

Controlling and monitoring inventory in a manufacturing unit is a tedious task, as there are a plethora of spare parts for different makes & models, brands, sizes, etc. kind of variants which need to be managed and made available when required. Your CMMS should make this task seamless.

Insights, Reports, & Analysis

The CMMS you select should provide insights like which equipment are due for maintenance, the cost of repairs, the inventory count or location, and similar data helping you to take quick and informed decisions. It should help you in accessing maintenance related reports easily and analyze critical situations.